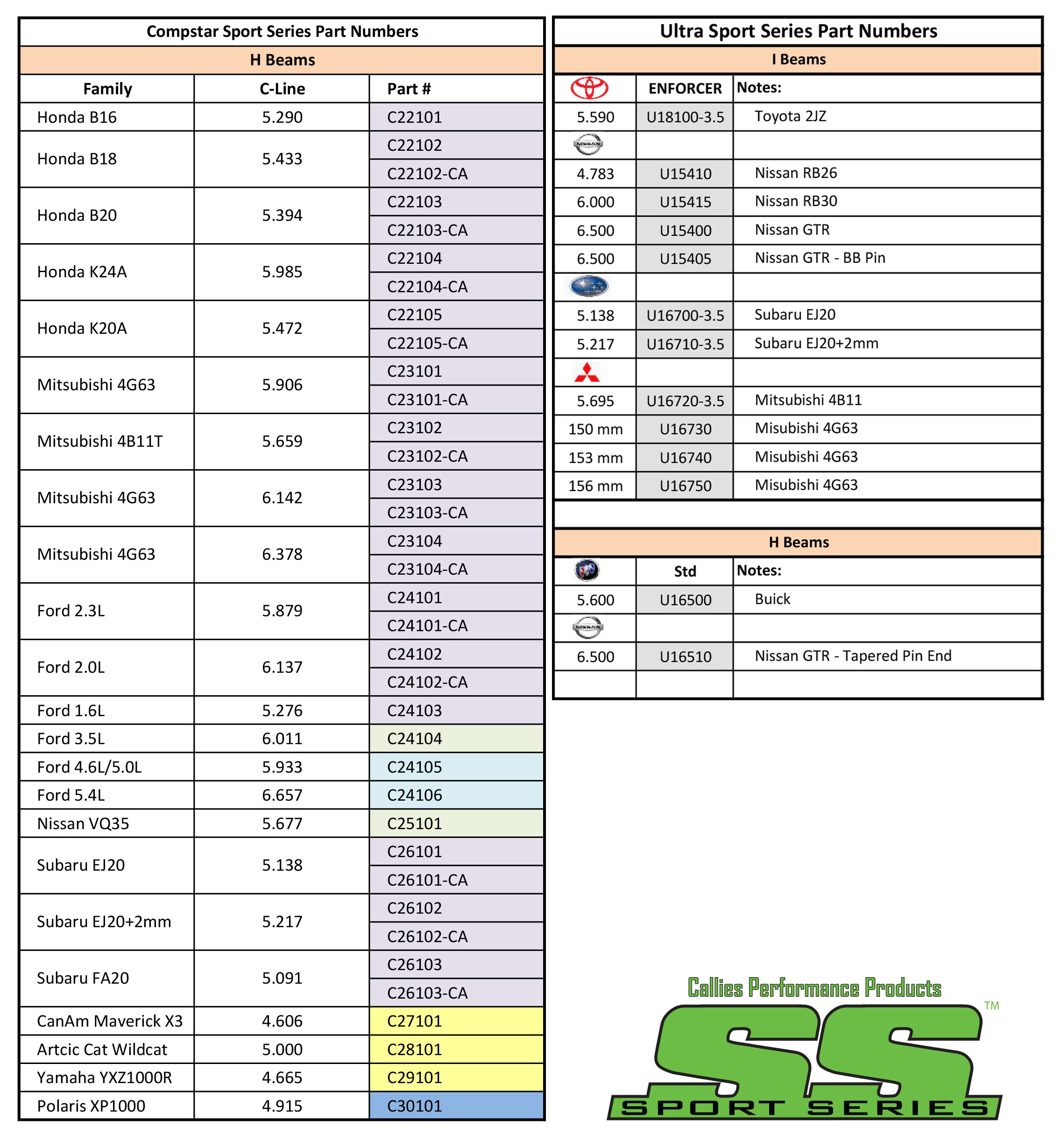

If using aftermarket rods or bolts follow the tightening procedure specified by the manufacturer and read utilizing fastener stretch below for more information.

Ls1 connecting rod bolt torque.

The procedures described in this step apply to engines using gm connecting rods and rod bolts only.

Eagle has arp custom make bolts to our specifications.

0 245 lw i beam sbc.

Lm7 5 3l vin code t.

The rod bolts were used at different times.

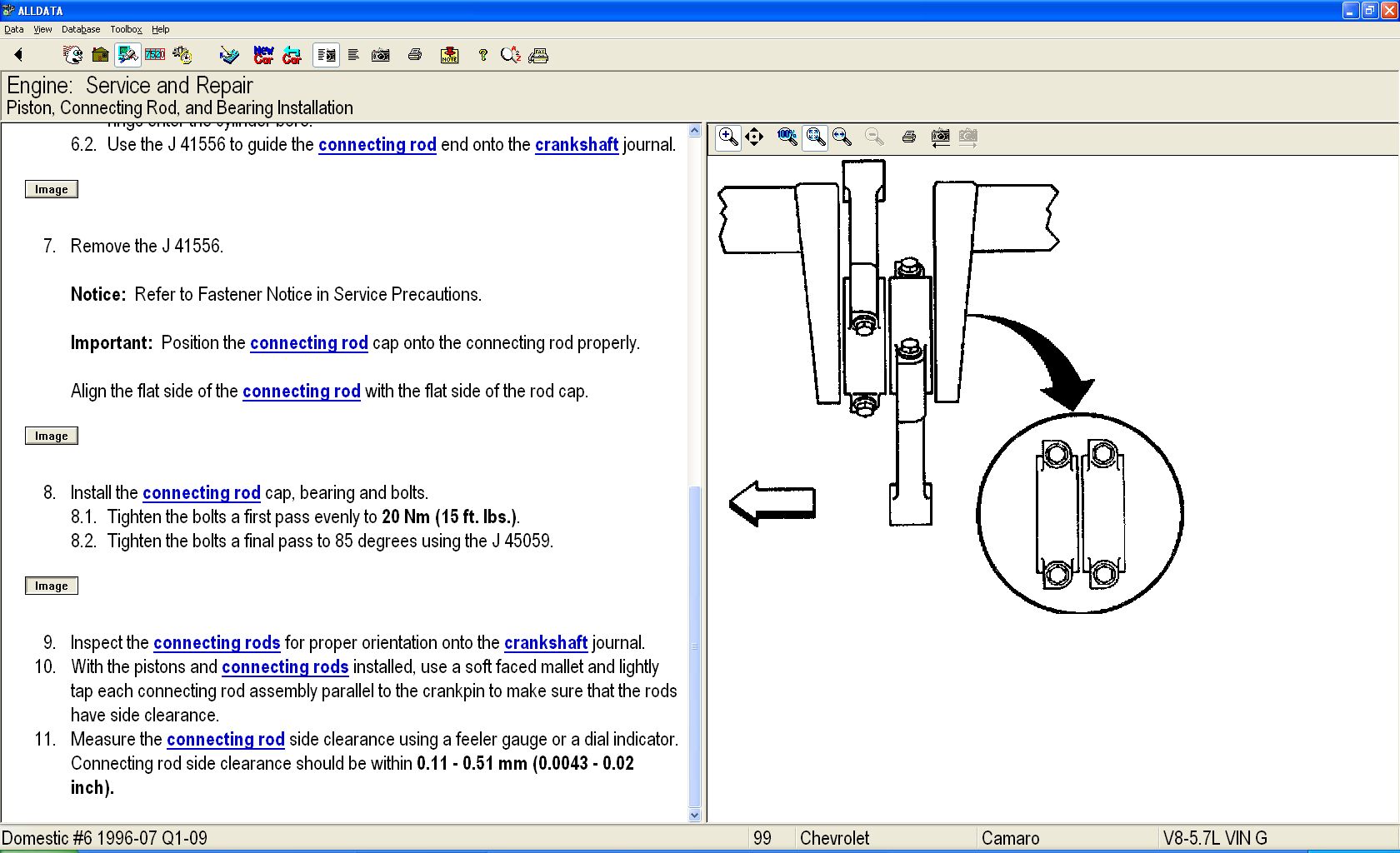

Connecting rod bolts second design first pass 15 lb ft.

Lr4 4 8l vin code v.

The following engines may have either design.

Eagle does not use off the shelf arp bolts.

Tighten connecting rod bolts torque fasteners note.

Coolant temperature gauge sensor.

What engines used them.

0 225 i beam sbc ls1 sbf.

Do not use torque specs for off the shelf arp bolts.

M9 x 1 x 43.

I didn t sit well with me.

15 lb ft.

Here is a diagram of some.

If you lost the connecting rod instruction sheet below are the proper torque specs for our rod bolts specs.

Ls1 5 7l vin code g.

Pin end widths sbc ls1 sbf.

Connecting rod bolts first design final pass 60 degrees.

Torque to yield tty cylinder head bolt size 1997 2003 8 m11 x 2 x 155 2 m11 x 2 x 100 5 m8 x 1 25.

Each have different torque specs so it s important to know the difference.

Each of which has a different torque requirement.

0 230 i beam bbc bbf.

Chevy ls1 engine specs ls family gen.

Crankshaft balancer bolt installation pass to ensure the balancer is completely installed.

0 195 h beam bbc.

3 5 7l aluminum block car engines.

1 005 thickness above the pin h beam sbc ls1 sbf.

Cylinder head bolt style.

I made a mistake last time and said torque your mains to 45ft lbs and 55ft lbs respectively.

Eagle rods are offered with a variety of different bolts.